|

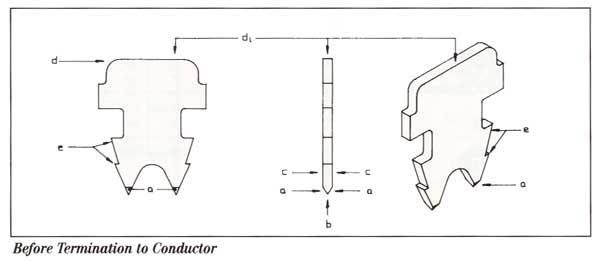

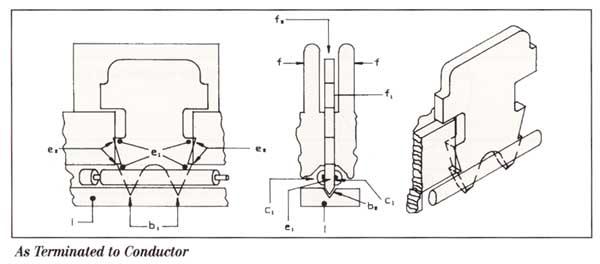

Piercing Tips

a- penetrate and pass

through insulation/conductor to reach final assembled position

Micro-conical Penetrating Points

b- extremely fine

conical points of contact blade piercing tips

b1- combs strands of conductor intop 2 groups

- micro size and

conical shape of points greatly reduce breakage and/or damage to conductor

strands during insertion

and penetration of contact blade

b2- forms retainer pocket in floor

(i) of plug and securely seats in retainer pocket

Mating Sidewalls to Conductors of

Cable

c- flat, parallel

sidewalls for mating to conductor

c1- blade sidewalls press the two

groups of strands apart to fully interpenetrate both groups conductor strands

encased

by insulation are in compression against both sidewalls to provide multiple

points of contact

- parallel

mating walls (unlike angled mating walls) maintain constant contact pressure

to conductor strands

- wraparound of

conductor strands on sidewalls provides significantly improved conductor

staking

- centering

alignment reduces standing wave reflections

Top Blade Mating Area fo Mating With Female Spring Contacts

d- curved, lead-in

surface

d1- large, rectantular

mating area for female spring contact (j)

- large, flat

mating area optimizes mated reliability by providing multiple points of

contact

Locking Barbs

e- locking barbs of low

contact blade to be anchored

e1- 4 anchoring points on each

contact blade

e2- unique point arrangement and

wall interlock secuure contact within the plug,

that cannot be dislodged under severe

vibration and shock

Contact Alignment

f- strong dielectric

barriers between contact blades

f1- contact is precisely vertically

oriented, centered between dielectric barriers

f2- provides optimum alignment with

spring contact of female connector

- prevents drag or

entrapment of female spring contact by eliminating contact blade slant

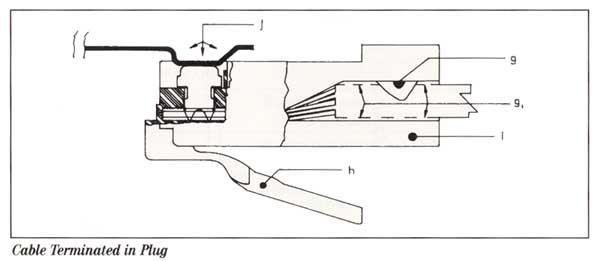

Cable and Plug Positive Retention

g- integral, molded

cable locking bar (strain relief)

g1- cable capture area in plug

housing

h- integral, molded

latching arm

- excellent

memory gives dependable springback, providing

positive retention within female connector

- high fatigue

resistance design prevents latching arm sag caused by field use

|

![]()

![]()

![]()